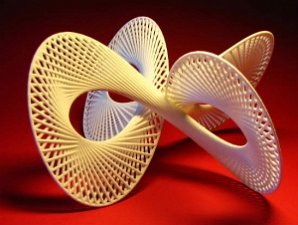

Is 3D Printing the Best-Ever Revolution?

By Billy Chan

Published on 05 May 2014

3D printers can do some amazing things, but what about when the product printed is wrong, or not exactly what is wanted? What happens with the material once done? Waste? Or recycling? This study shows some of the environmental impact from an energy standpoint. In a comparison report by Jeremy Faludi, a Fused Deposition Modelling (FDM) printer (e.g. RepRap, Makerbot) can produce insignificant percentage of waste in theory, unless the model was produced without any supporting material to shore up during printing. This, however, is unlikely to happen in most cases. Needless to say, a 3D inkjet printer by layering with polymeric ink and UV-cures produce 40-45% ink waste on top of non-recyclable support material.

Jeremy then further tested the sustainability between the two 3D printers and a computer-controlled mill by conducting a life-cycle assessment (LCA) with comparable parameters. The result suggests that by maximising production with the fewest machines for production around the clock, the environmental impact could be reduced by 10 times, when compared to using the same machines for one time jobs, with the power on weekly.

At high product rates, when the FDM tool was fully turned off when not being used, it won with far less environmental impact than the inkjet printer and the mill by roughly 50% and 1/3 respectively. The inkjet 3D printer usually scored worse, but scored better when it was run at maximum efficiency than the mill. However, the mill would scored the best in high-usage situations yet the worst in waste measurement.

In Jeremy’s concluding statement: “The final verdict, then, is that 3D printing can be greener, if it’s the right kind (FDM); but again, the biggest environmental win comes from sharing the fewest tools so each has the most utilization.”